Imaging methods are increasingly used in industrial productions of almost all industry segments.

This is especially true for segments with highly automated manufacturing processes, like the production of printed circuit boards (PCBs) in the electronics industry.

The electronics industry has experienced a steep increase in demand and therefore solid growth recently. Combined with industry characteristics like a strong pressure for innovations, this leads to short product life cycles, fast innovation sequences and the need for flexible production processes.

Cameras / Machine Vision components play an integral part in this flexibility.

Depending on the intended use, standardized camera modules can be selected according to their specific strengths. Following are a few examples of machine vision applications in the manufacturing process of electronic components and devices.

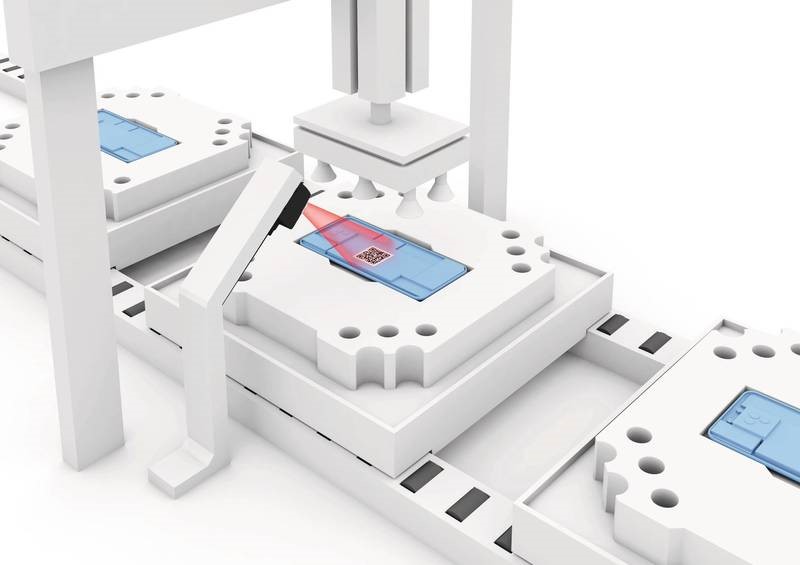

Identifying data matrix codes on electronic components

Figure 1: Traceability of components

A rather unspecific task that occurs in almost every industry segment is the identification of components and assemblies.

In the assembly process, all components and assemblies can be uniquely identified and thus traced by means of 2D codes applied to them. Camera-based code readers can read even the smallest DataMatrix codes (e.g. on battery cells or printed circuit boards).

This usually does not require a high-end industrial camera, but so-called code readers.

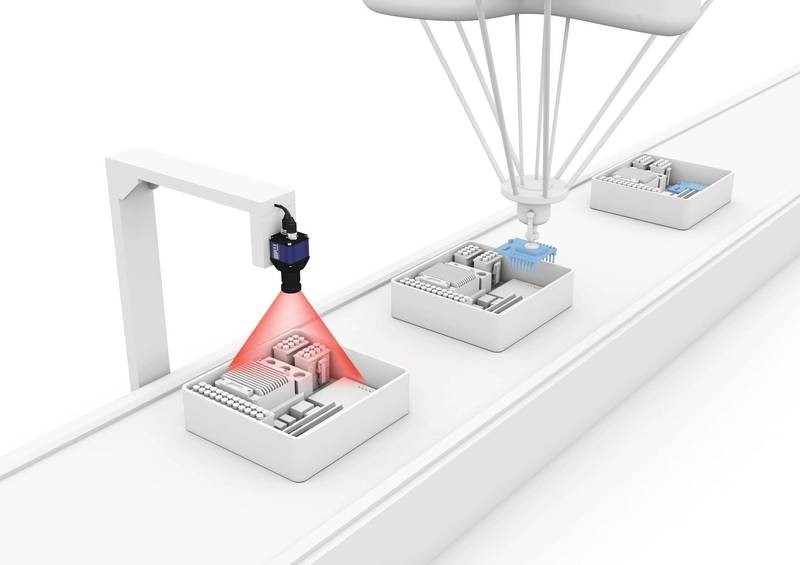

Precise robot control in pick-and-place applications

Figure 2: 2D position recognition

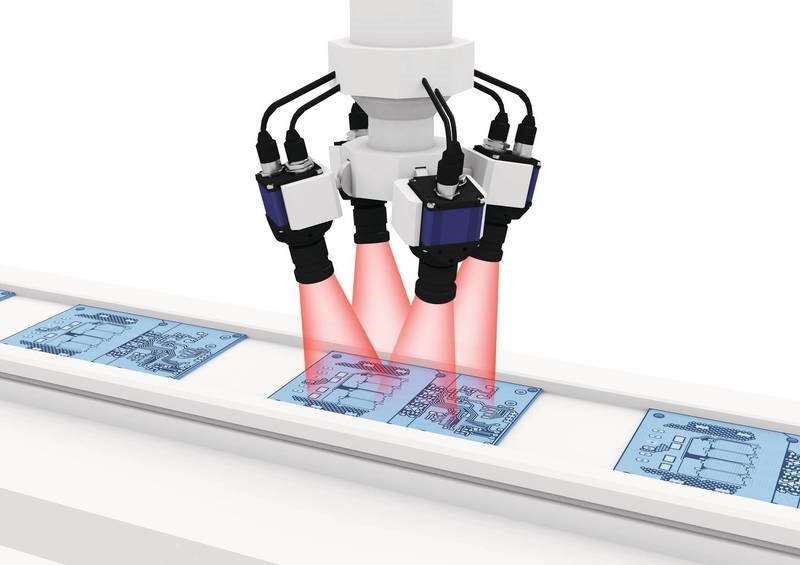

Figure 3: Robot gripper with 3D camera module

Robots have become an indispensable part of modern manufacturing. Rising labor costs, as well as stricter quality requirements, increasingly demand robot-based solutions for the electronics industry.

Industrial cameras give your robots a sense of sight. This enables easier parts handling, more precise positioning of the robot arm, more targeted gripping of parts and more accurate position control. Here, industrial image processing with 3D camera modules enables high accuracies in object detection and thus error-free assembly of device modules.

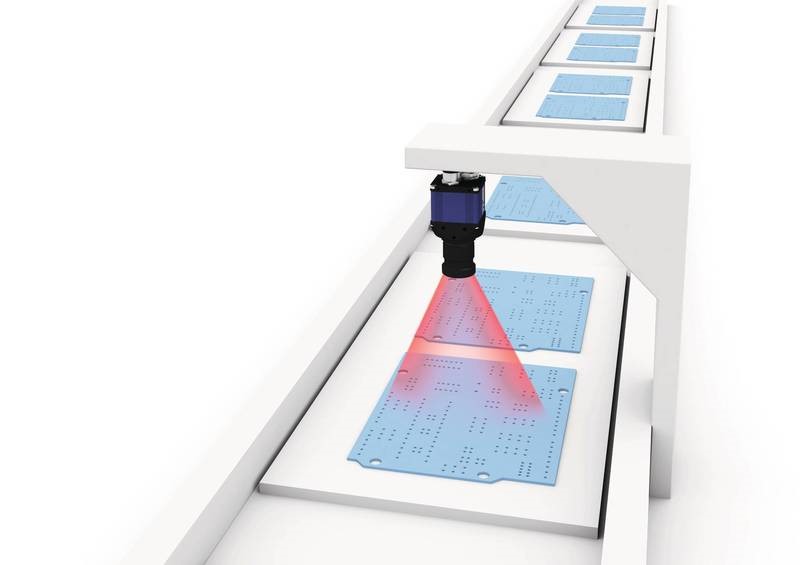

Inspection of components

Figure 4: Inspection of an empty printed circuit board

Figure 5: Solder paste inspection

Figure 6: Inspection of an assembled printed circuit board

Increased efficiency and quality demands require continuous quality controls. These can be automated with industrial cameras.

In the production of printed circuit boards, for example, inspections are common after each essential process step. For example, the contours of the blank circuit boards as well as their holes are checked to ensure that the correct blank has been inserted (Figure 4).

Errors in solder paste printing are the most common cause of defects, but these are not detected until after reflow soldering. Industrial cameras enable fast and precise inspection of the smallest solder paste structures to prevent exactly this and save costs due to rework (Figure 5).

Finally, the applied components are also checked for correct placement (Figure 6).

All these process steps with subsequent quality control run fully automatically and reliably – not least due to machine vision.

Further applications for industrial cameras, e.g., in the field of life sciences, can be found HERE.

For general information about standardized camera modules, you can visit MATRIX VISION