In “classical” industrial automation (factory automation) standardized sensors control the manufacturing processes. The automation of laboratory tasks (lab automation) demands additional requirements.

Miniaturisation plays an important role, as lab equipment typically is designed in smaller form factors compared to production machines in industrial manufacturing.

Quite often challenging is the mini size of the objects, yet the detecting distance in the application will hardly vary.

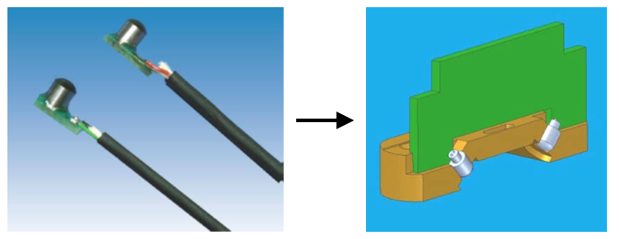

Miniaturized modules, consisting of lenses, sender and receiver elements are positioned with defined alignment. This allows the creation of optimized sensors for the specific application in combination with dedicateded receiver and amplifier electronics.

Here are some examples: Link

A typical application of optical sensors in lab automation is the detection of transparent slides. Since their edges have different surface properties, the sensors must tolerate this variance. Special optical sensors with a very small diameter of the light beam and the smallest possible opening angle are used for this purpose.

For liquid handling in the context of laboratory analysis optoelectronic sensors offer advantages for monitoring the processes.

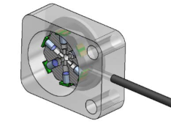

One field of applications is the detection of microbubbles with specially optimized sensors.

Links to the application and to a product example:

BOH001H (BOH ZR-T16-002-S49F-SA1) Micromote – optical sensor heads – BALLUFF

Lab-on-a-chip will gain tremendous market share within the next years

Examples for sensors in life sciences: