Overview of Smart Automation and Monitoring System Smart Sensor Functions

Find an overview about the smart sensor features of SAMS in this blogpost

Signal Quality

The signal quality information can support you as the user of Smart Automation and Monitoring System (SAMS) products during setup of the machine as well as predictive maintenance during operation.

The quality of the incoming signal is monitored. The impairment of the signal quality can have different causes in different devices. With optical sensors, for example, a reduction in the signal quality can be attributed to a dirty lens. With an inductive sensor, this can be caused by being too far from the target.

With RFID systems, e. g. through metallic foreign bodies in the work area.

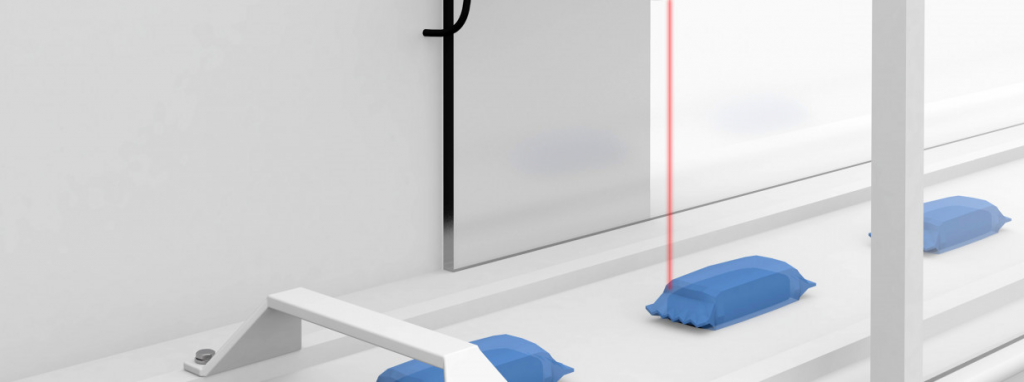

Photoelectric Sensors

With an Optical Sensor (BOS) during setup you can adjust location, alignment and environmental conditions to reach a satisfying level of signal quality out of your application. During operation, through regular logging of the signal quality, slight deviations in alignment and changed environmental conditions (e.g. dust / oil mist on the lens) can be detected.

More on photoelectric sensors with conditon monitoring

Inductive couplers

Inductive couplers (BIC) are now considered indispensable in many different manufacturing applications. With their non-contact transmission of data and power, they have gained favor over plug-in contacts. The maximum transmittable coupler power plays a central role in many applications. Monitoring signal quality during setup you can adjust the alignment and distance between Base and Remote to get maximum power transmission.

If signal quality is getting weaker during operation it is an indicator of changed distance or miss alignment between Base and Remote.

If you face the weaker signal quality during operation, you will be able to react and fix the problem before downtime occur.

Condition Monitoring with SAMS

Additionally, the Smart Automation and Monitoring System Product monitors the signal quality and provides an IO-Link event if the signal quality falls below an adjustable threshold. This threshold (0 to 100%) can be set according to the application needs and is used to define two states of the signal quality. Equal or above the threshold, the signal quality is considered good so no action needed, below the threshold, the signal quality is considered bad, you should react.

More information about the SAMS system you can find here.

[…] Signal quality […]